Ecoslops was born from one observation: too many hydrocarbon residues from shipping end up being incinerated or, worse still, dumped in the oceans.

A practice both harmful to nature and the protection of natural resources, uncontrolled dumping of these residues could be avoided through their regeneration. While not a renewable energy, this energy source can now be regenerated by Ecoslops.

MARITIME POLLUTION

The constant growth of maritime trade since the 20th century has led to a significant increase in the pollution of our seas and oceans. During normal operation, ships produce a variety of oil waste, such as slops and sludges.

90%

of commercial trade

is by sea.

(source: ICS Shipping)

1 to 2%

of the quantity of fuel consumed onboard a ship will end up as sludge.

The maritime industry consumes 250 million tons of oil per year, generating between 2 to 4 million tons of sludge annually.

A 50,000-horsepower container ship, for example, generates 1.6 tons of hydrocarbon waste a day, almost 1% of its heavy fuel consumption.

At one time, this waste would have been dumped at sea.

The amount of oil waste discharged at sea is estimated at between

700,000 and 1.3 million

tons each year (various sources)

THIS NEED TO PROTECT OUR FRAGILE ECOSYSTEM MEANT THAT MARITIME TRADE HADTO HAVE ITS OWN SET OF REGULATIONS.

The first international textappeared in 1954 in the form of the OILPOL Convention (International Convention for the Prevention of Pollution of the Sea by Oil). Butthe measures were not restrictive or repressive enough. A new text, adopted in 1973 and subsequently amended in 1978, was the MARPOL 73/78 Convention. Mainly intended to reduce all forms of pollution caused by ships (sea, land, air), the OILPOL Convention remains in force today and has helped to enforce the collection and treatment of waste on land.

In 1973, the IMO (International Maritime Organization) adopted the MARPOL Convention, setting the guidelines for the collection of waste generated at sea and its treatment on land.

In 1978, the IMO made some amendments and added an implementation protocol. The convention, now called MARPOL 73/78, mainly covers the management of waste generated by maritime transport. Ratified by all major international shipping countries, it was transposed into European law in Directive 2000/59/EC. The MARPOL Convention must therefore be observed by all ships.

This convention drastically reduces the dumping of slops at high sea and prohibits their proximity to coastlines and in most of Europe’s seas. The considerable surplus, along with other waste, must be deposited at Port Reception Facilities (PRFs) at the expense of shipowners. The regulations also place restrictions on ports with collection and waste treatment infrastructures.

While a few cases remain, the practice of legal degassing at sea is set to disappear. The restrictions imposed by the MARPOL Convention concerning the concentration of products allowed to be discharged, the speed of these operations, and the monitoring of quantities, have encouraged shipowners to dispose of their waste portside.

These regulations are further enforced by frequent ship inspections and tracking by satellite and plane (EU Erika II Measures). These inspections, relying largely on better waste traceability and heavy sanctions, have been effective in fighting illegal degassing at sea (although 1 million tons are still estimated to be dumped each year).

Once on land, the storage and treatment of this industrial waste are governed by a different set of regulations. Treatment sites must comply with the EU’s SEVESO I and II Directives to obtain an operating permit,andwith the relevant environmental law (emission of pollutants and greenhouse gases), particularly those targeted by European Directives 2000/76/EC and 2008/98/EC under the polluter-pays and producer responsibility principle.

Industrial waste is also governed by the Basel Convention. Its export outside the European Union is strictly regulated.

More information available on the IMO website

A port reception facility (PRF) can be a fixed, floating, or mobile structure providing a collection service for ship-generated waste. The scope of a PRF is defined in several sets of regulations and principles: Sustainable Development Goal no. 14 of the United Nations, the UNCLOS Convention, the MARPOL Convention, and the European Directive on port reception facilities. These facilities generally comprise four key components:

- waste reception and handling plan for each port

- waste information and monitoring system

- advance waste notification and waste delivery receipt

- fee system for waste

The European Union transposed the MARPOL Convention into EU Directive 2000/59/EC. EMSA (the European Maritime Safety Agency) is responsible for introducing measures to actively fight the uncontrolled dumping of waste at sea.

Under the terms of the directive, “ship-generated waste” is understood to mean all waste, including sewage, and residues other than cargo residues, which are generated during the service of a ship and fall under the scope of Annexes I, IV and V to MARPOL 73/78, and cargo-associated waste, as defined in the Guidelines for the implementation of Annex V to MARPOL 73/78; “cargo-associated waste” is understood to mean the remnants of any cargo material onboard in cargo holds or tanks which remain after unloading procedures and cleaning operations are completed, including loading/unloading excesses and spillage; “port reception facilities” are understood to mean any facility, which is fixed, floating or mobile and capable of receiving ship-generated waste or cargo residues.

The directive applies to all EU ports and all ships, irrespective of their flag, calling at an EU port. The ports are required to provide adequate facilities in line with the port’s importance, the category of the ship, and the type of waste discharged, to avoid causing undue delay to the ships that use them, which is subject to the payment of compensation.

The captain of a ship destined for an EU port is required to give prior notification. This notification must mention the last port of discharge, the amount of remaining waste, and the date of discharge. The captain is also required to discharge the ship’s waste before leaving an EU port, except for certain exemptions and if the captain can prove there is sufficient storage capacity onboard the ship. If there is proof that a ship has returned to sea without discharging and with no exemption, the next port of call is alerted. The ship must then be inspected at the next port before any cargo is handled. In all cases, 25% of ships stopping at EU ports can be inspected in accordance with the Port State Control.

More information available on the EMSA website

Adopted in 1992, the Basel Convention aims to control transboundary movements of hazardous waste to prevent large-scale dumping of waste by certain countries.

The waste covered by the convention primarily covers alltypes of industrial, pharmaceutical, and chemical waste, including all hydrocarbon waste and hydrocarbon/water mixtures.

The Basel Convention was adopted by more than 165 countries around the world. It was transposed into European law in Regulation (EC) No. 1013/2006.

Its prime aimis to establish measures for the traceability of waste to predict and limit its movement. The convention also promotes the environmentally sound management and recovery of waste.

For example:

– The export and import of waste to/from a State that is not a signatory to the convention is prohibited;

– The export of waste to a signatory-State is prohibited if the State does not provide written consent;

– Transboundary movements shall only be authorized if the transportation and treatment of the waste is in no way hazardous;

– The waste must be packaged, labeled, and transported in compliance with international rules;

– Any State may add its own supplementary conditions to this convention.

Consult the Basel Convention

The management of waste on national territory is the responsibility of each State.

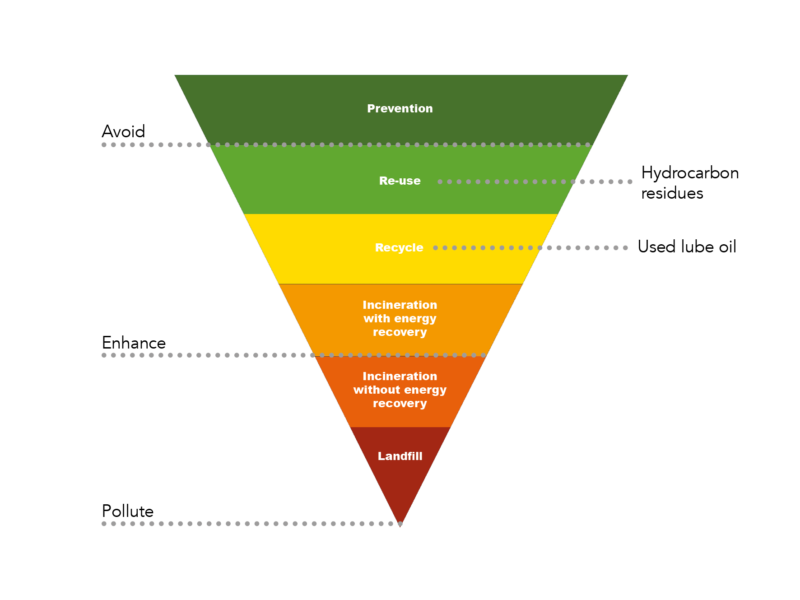

The European Union steers national policies towards the recovery of waste through Directive 2008/98/EC:

– Polluter-pays principle: the cost of managing waste must be borne by the waste producer;

– Principle of proximity: waste must be managed as close as possible to the place in which it is generated;

– Principle of producer responsibility for any pollution that may be caused by this waste.

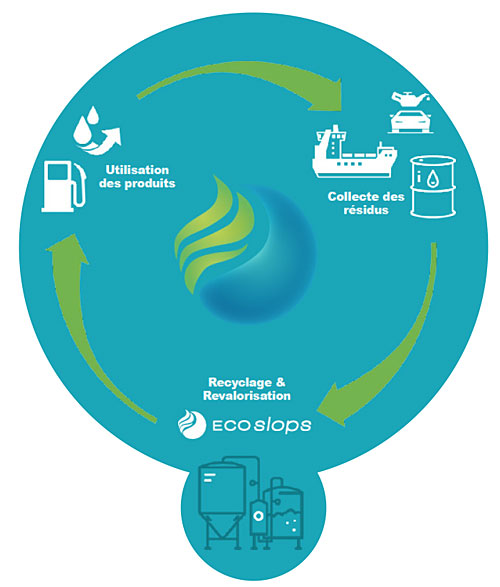

Europe is entering the circular economy and low-carbon green growth era. One of its ambitious Green Deal goals is to use resources more economically and to limit the exploitation of natural resources. Part of its solution involves the large-scale promotion of recycling waste to move ever closer to material circularity.

Ecoslops is proposingpartnerships with collectors of slops from ships and industries that generate hydrocarbon residues, to purchase their waste. Giving financial value to this waste, regardless of ever stricter regulations, helps avoid its discharge into the oceans or dumping in inappropriate places.

In this era of energy transition, recovering this waste improves the material footprint of hydrocarbons by avoiding new extractions.

UNITS DESIGNED FOR THE CIRCULAR ECONOMY

By building units designed to regenerate waste, the company promotes the recycling and reuse of materials. This is how Ecoslops brings oil into the circular economy and improves the efficiency of this resource.

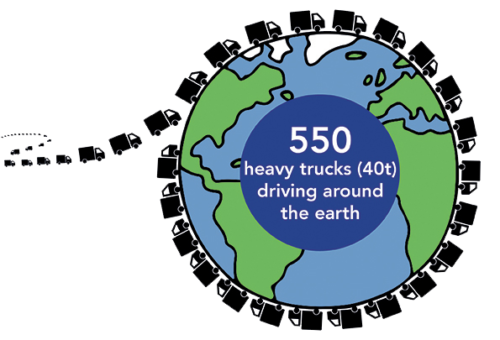

Ecoslops contracted a climate consultancy firm Carbone 4 to quantify the impact of its activities on greenhouse gas emissions (GHG).

For a unit like the one at Marseille (30,000 tons/year nominal capacity), Carbone 4 pointed out that the P2R process could reduce production emissions by a third, compared to the standard method based on crude oil extraction. Our business model also helps to preserve the stock of raw materials.

“Avoided emissions” are the difference in the level of GHG emissions compared to a reference scenario, caused by an “intervention” by the organization within its environment (Carbone 4 definition, Net Zero Initiative Guidelines)

generated for 30,000 tons of production (according to Carbone 4 Study)

6

ktCO2eq.

19

ktCO2eq.

Conventional production cycle

The 2018 study results indicate that a site like La Mède would alone reduce emissions by 13 ktCO²eq/year.

Ecoslops’ economical waste recovery process is a financial incentive for shipowners and other waste producers to have their residues treated more transparently, avoiding uncontrolled dumping at sea (or elsewhere).

Carbone 4 also points out that before Ecoslops’arrival at a site like La Mède, oil residues would generally be used by cement plants as a start-up fuel. After Ecoslops’ arrivalon site, these manufacturers are forced to use other sources of energy, with natural gas being the most likely substitute fuel under the current technical and economic circumstances (less carbon-intensive than oil residues). In the case of La Mède, this fuel substitution represents an additional GHG reduction of 9 ktCO²eq/year.

13 ktCO²eq + 9 ktCO²eq =

22 ktCO²eq

of GHG

emissions avoided

per year,

i.e., equivalent to:

REDUCE BY A THIRD

emissions from manufacturing,

by producing new, low-carbon

petroleum products.

22 ktCO2eq

of emissions avoided per year, for a site

like La Mède, processing 30,000 tons

of dehydrated residues per year.

FULL TRANSPARENCY

AND TRACEABILITY

of the waste

treatmentprocess.

A REDUCTION

in uncontrolled dumping at sea

Helping

TO IMPROVE THE MATERIAL FOOTPRINT

Our business model also helps reinforce the Sustainable Development policy of ports, while enabling them to offer new value-added services and create skilled jobs. Each stage of the process is traceable and in compliance with international regulations on the management and treatment of hydrocarbon waste.

All products from our Sines plant in Portugal have been awarded ISCC PLUS certification.

ISCC PLUS certification is a voluntary sustainability certification for industrial applications, food and feed markets, and biofuels outside the EU. It is a proven tool for verifying compliance with sustainability and traceability requirements, and a standard recognised by all stakeholders for recycled materials. It ensures traceability throughout the supply chain and verifies that companies comply with environmental and social standards.

This certification provides credible and transparent proof that the recycled fuels produced by Ecoslops Portugal contribute fully to the circularisation of the economy, an additional advantage for all our environmentally conscious customers.

IN JANUARY 2024, ECOSLOPS’ P2R TECHNOLOGY HAS SUCCESSFULLY RENEWED ITS “EFFICIENT SOLUTION FOR THE PLANET” LABEL BY THE SOLAR IMPULSE FOUNDATION, PROMOTING EFFICIENT AND COST-EFFECTIVE SOLUTIONS THATPROTECT THE ENVIRONMENT.

Our mission is to support the energy transition and environmental conservation through innovations that help to preserve the stocks of raw materials and avoid pollution.

Our corporate social responsibility strategy is developed around this mission and the main guidelines of ISO 26000: governance, human rights, employment relations and conditions of work, the environment, fair practices, consumer issues, and local communities and development.

Our top priorities for 2024-2026, which weredefined based on an analysis of our key issues under ISO 26000, are as follows:

• Pollution prevention

• Occupational Health & safety

• Sustainable consumption

• Sustainable use of resources

• Value & wealth creation

• Relations with stakeholders

UNITED NATIONS GLOBAL COMPACT &SUSTAINABLE DEVELOPMENT GOALS

Since 2019, Ecoslops has been actively engaged in the social responsibility initiative of the United Nations Global Compact and its ten principles concerning human rights, labor, environment, and anti-corruption.

Ecoslops’ aim is to contribute to the UN’s Sustainable Development Goals (SDGs) and spread these values among its stakeholders, making sure that the Global Compact’s ten principles are applied in practice.

Every Ecoslops employee benefits from health cover, giving access to quality essential health services and to safe, effective, quality and affordable essential medicines and vaccines.

The company promotes the development of human capital and encourages continuing education. It also offers flexibility to students, so that they can continue their studies while working, and trains interns.

Ecoslops supports the more efficient use of resources and has established a system of sound ecological management of oil residues, considerably reducing all associated pollution (water, air, soil) and recycling them into new products. The company is acutely aware of its energy consumption and the efficiency of its processes. More than 99% of our raw materials are made up of waste.

Recycling hydrocarbon residues of maritime origin helps to reduce deliberate pollution by hydrocarbons, of which there are still too many (bilge dumping).

Ecoslops has developed a guide to business ethics, including points on professional equality, discrimination and the fight against corruption. It regularly works with external stakeholders on technical and CSR issues.

ENVIRONMENT

Environmental protection is the foundation on which Ecoslops was built. Our CO2 reductions are made upstream in the production process when the business model is being developed and the units designed, bringing hydrocarbon residues into the circular economy.

Since concern for the environment is in its DNA, Ecoslops constantly endeavors to protect our natural resources and consume water and energy more efficiently.

The FAPU (Fight Against Plastic Use) plan has led to the removal of all single-use plastic company-wide.

+191 980

tonnes of residues recycled as fuel

at 31/12/2023

98,5%

of our raw materials

are waste

CO2 emissions ratio per ton produced

0,22%

4,40

EXTERNAL ESG EVALUATION

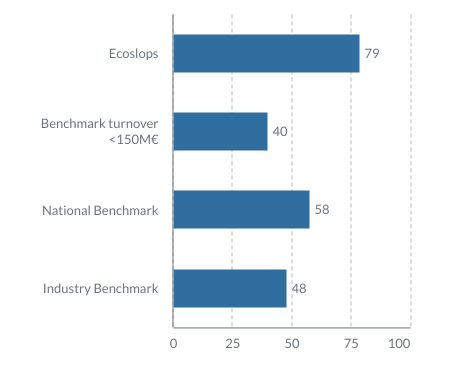

Since 2018, Ecoslops has been assessed annually by Ethifinance ESG ratings (formerly Gaïa Research), a rating agency, which specializes in ESG performance ratings for SMEs and mid-cap companies listed on European markets.

For the 2022 campaign (done in 2023), Ecoslops received a rating of 79/100, an increase for the 5th consecutive year.

24/310

(39/371 for the 2021 campaign)

10/416

(12/126 for the 2021 campaign)

4/272

(7/76 for the 2021 campaign)

Ecoslops continues to rank above the national, economic, and sector benchmarks, and was rewarded this year with the 1st place in the top five of industrial businesses-commercial and professional services sub-sector.

GOUVERNANCE

Ecoslops has a Good Conduct Guide for promoting ethical business practices, which is updated regularly and distributed to new employees when joining the company.

> Consult our Good Conduct Guide

The company has a notification system to inform employees and partners about ethical issues : compliance@ecoslops.com

For more information on the Board of Directors:

> Consult our Corporate Governance Report (in french)

> Consult the Board’s Rules of Procedure (in french)

STAKEHOLDERS AND

LOCAL COMMUNITIES

Ecoslops places great importance on engaging with its stakeholders.

We are convinced that a policy of listening, discussing, and putting forward proposals makes the company stronger and more adaptable to the different challenges and risks it faces.

Ecoslops also develops skills by recruiting within the local communities in which it operates and training local workers in its various specializations.

All Ecoslops employees are paid above the local minimum wage.

Inspired by the best practices in the sector, our Responsible Purchasing Charter provides the framework for Ecoslops’ purchasing strategy. Mindful of its duty of care, the company actively seeks to reduce health and environmental risk and ensure greater respect for human rights throughout its supply chain.

This charter must be signed for any purchase over €100,000.

SOCIAL

Health & Safety

Ecoslops places particular importance on the health

and safety of its employees.

- SHEQ Policy

- Golden Rules

- Informação a comunicar ao público_2025

- PPAG_Ecoslops Portugal

- Política SGI_Ecoslops Portugal

- Policy IMS_Ecoslops Portugal

0 serious accidents since the start-up of its first unit in 2015.

“Concern for man and his fate must always form the chief interest of all technical endeavors”.

Albert Einstein

Diversity and equal opportunity

• Ecoslops has signed the United Nations Women’s Empowerment Principles

100% of employees considering the dignity of women to be respected in the company (in-house survey – December 2021).

of women

(+0,2%)

100%

0

cases of discrimination reported since the company was founded

99%

(vs 67% in 2022)

Quality of Life at Work

Ecoslops is committed to providing a pleasant working environment. Employees are regularly consulted on a variety of issues and enjoy various benefits, including supplementary healthcare, flexible working hours, and time management when production constraints allow. All staff benefit from an annual free-share distribution plan.

Ecoslops is a company involved in the maritime and energy sectors and the development of local communities. It is also a member of several associations:

GREEN AWARD PROGRAM « Incentive Provider »

Green Award is a non-profit organization that certifies the environmental performance of companies in the maritime transport sector. A Green Award certificate puts shipowners and charterers a cut above the rest, demonstrating their commitment beyond the regulatory requirements. Totally independent, the Green Award Foundation audits and certifies ships based on a set of pre-defined specifications regarding safety, quality, and environmental issues.

Ports and maritime service providers (“incentive providers”) on the one hand, and shipowners and charterers on the other, have all joined the Green Award program to reduce the risk of accidents and promote an environmentally responsible, high-quality shipping industry that is economically viable: a key factor for competitiveness in the eyes of their customers.

Since April 2016, Ecoslops Portugal and the Green Award Foundation have offered an incentive program for ships with the Green Award Label in the Port of Sinès: they receive a 25% discount on the cost of removing their slops.

EUROSHORE

Euroshore’s mission is to contribute to the conservation of the oceans by leading the best practices in waste management for the maritime industry. To fulfill this mission, this association of providers of port reception facilities in Europe and overseas endeavors to:

• Promote the use of port reception facilities

• Promote the efficient and environmentally sound disposal of ship waste

• Promote relevant international policy, procedures, and standards of competence for the collection and processing of ship waste

• Promote healthy and fair competition.

This monitoring, reviewing, and constructive dialogue process both at international and regional levels, enables Euroshore members to stay properly informed and helps them provide the shipping industry with adequate and environmentally sound waste management services.

FRENCH MARITIME CLUSTER (CMF)

An association created by and for businesses operating in the merchant shipping sector, CMF is comprised of companies of all sizes, along with competitiveness centers, federations, associations, laboratories, research centers, educational and training organizations, local authorities, economic stakeholders, and the French navy.

The CMF assists members with the sustainable and responsible development of their activities and projects, in both France and abroad, through a range of initiatives.

COMSINES

Working with the residents of Sinès, COMSINES is a non-profit association founded in 2015. Organizing joint initiatives between local businesses and entities representing the community of Sinès, it aims to fulfill the expectations of local residents. Governed by a set of values essential for implementing its strategy and achieving its objectives, the association has established various task forces (“Heritage and Culture”, “Competitiveness, Logistics and Transportation”, “Prevention and Safety”, and “Health and Environment”), in which Ecoslops Portugal participates from time to time.

ADEME Club international

Since 1997, ADEME Club International has brought together innovative French eco-enterprises which are developing some of their business in international markets or looking to export. Established and managed by ADEME (the French Agency for Ecological Transition tasked with implementing public policy on environment, energy, and sustainable development issues), ADEME Club International serves as a platform for its members to communicate with French public actors in charge of these three issues and foreign trade. It covers the entire spectrum of the ecological and energy transition:

• Renewable energies and energy efficiency

• Sustainable cities, buildings, and urban planning

• Air quality

• Circular economy, waste, and soil decontamination

• Water and biodiversity

• Environmental management

• Climate change mitigation and adaptation

EVOLEN

EVOLEN’s mission is to promote French excellence in the hydrocarbons and new energies industry worldwide. The knowledge and expertise of its 1,350 members – 250 companies and 1,100 professionals – covers the entire spectrum of hydrocarbons (exploration, production, development, logistics, refining, distribution) and new energies (offshore wind, onshore wind, marine energies, energy storage, etc.).

WORLD ALLIANCE SOLAR IMPULSE

Ecoslops is a proud member of the World Alliance for Efficient Solutions uniting all key players in the clean technologies sector to build synergies, help solutions providers and investors connect, and present clean and profitable solutions that have the potential to meet today’s environmental challenges.