Notre mission est de contribuer à la transition énergétique et à la préservation de l’environnement par le biais d’innovations permettant de préserver les stocks de matières premières et d’éviter les pollutions.

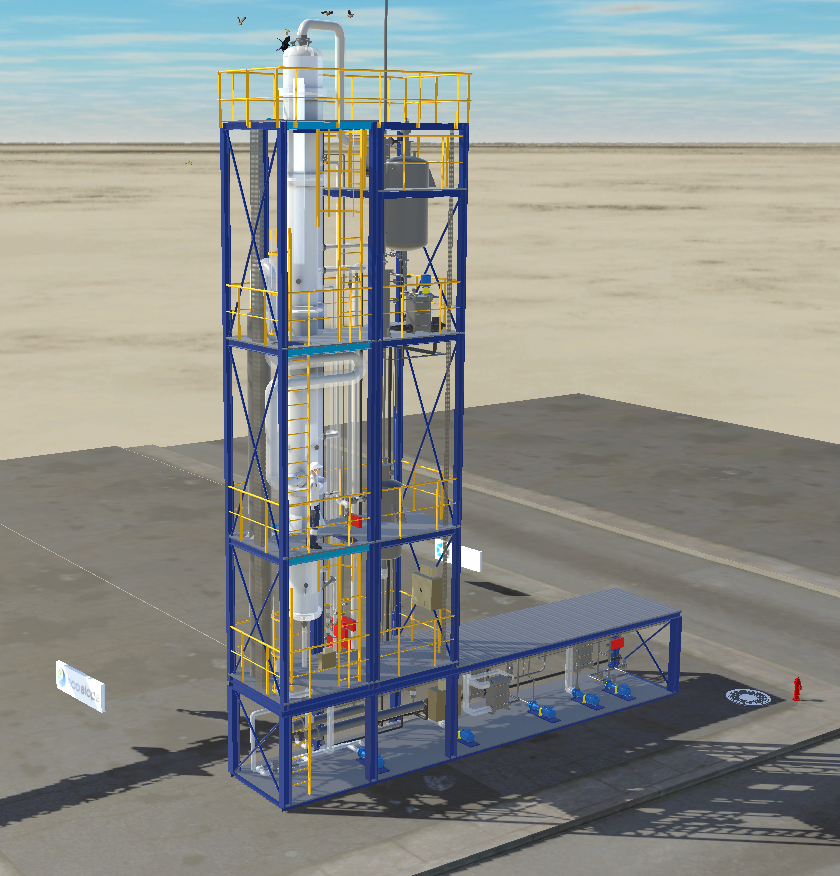

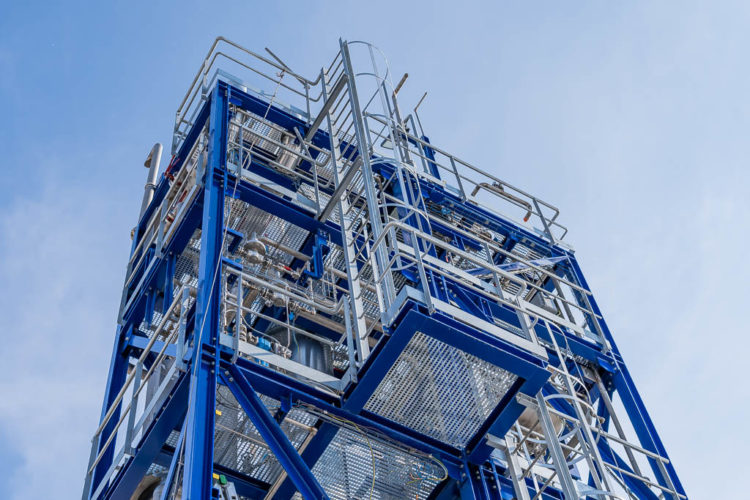

Notre ancrage dans l’économie circulaire, nos technologies et notre savoir-faire permettent une fabrication à faible intensité carbone de nouveaux produits énergétiques.

Ecoslops préserve la planète de différents types de pollutions :

- Les pollutions liées à l’extraction de matières premières : Notre taux de rendement des déchets traités est de 98%. Cela permet d’améliorer l’empreinte matière des hydrocarbures, en évitant de nouvelles extractions.

- Les pollution environnementales liées aux déversements des déchets hydrocarburés dans le milieu naturel : En redonnant une valeur aux déchets hydrocarbonés (résidus pétroliers et huiles de vidange), Ecoslops incite les producteurs de ces résidus à les décharger dans les ports via les filières de collecte existantes, évitant ainsi qu’ils ne soient déversés dans le milieu naturel et endommagent la biodiversité marine ou terrestre.

- Les pollutions atmosphériques liées à la production de produits énergétiques : Nos solutions industrielles innovantes permettent de produire des combustibles et des bitumes légers à partir de déchets hydrocarbonés, en émettant 3 fois moins de CO2 que le processus traditionnel de production pétrolière (voir notre rubrique Développement Durable pour plus d’information).